|

| > iacl.org > Tire Page

Tire Page

Jasper Rebuilt Hub on 1998 Coachmen Ford E-350 After a 3 month stay at Front End Alignment in Punta Gorda, We get our camper back with a new axle and they were finally able to source needed hubs and axles. First trip out it seemed fine. 2nd trip out to northern Florida - something breaks loose and we wind up at an auto shop after having been towed. Hopefully they can rapidly fix or tell us whats wrong.

New Front Brake Calipers, Rotors and pads - E-350

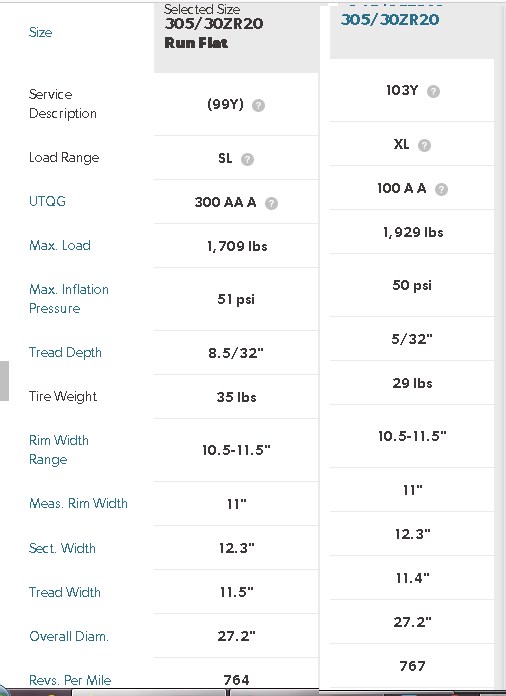

305/30R20 Michelin Runflat and Goodyear Spec Comparison A quick look at the feasibility of finding some run-flats for the Tesla X Plaid. The 5,600 pound car (including 200 lb driver) puts about 1,400 lbs on each tire. The Michelin's have better traction and speed rating, and according to reviews, a bit noisier on the bumps. SL and XL are the "same" 4 ply tire with about a 12% difference. [In trailer parlance higher load ranges had more ply, including sidewall ply as one got into load range E (10 ply)]

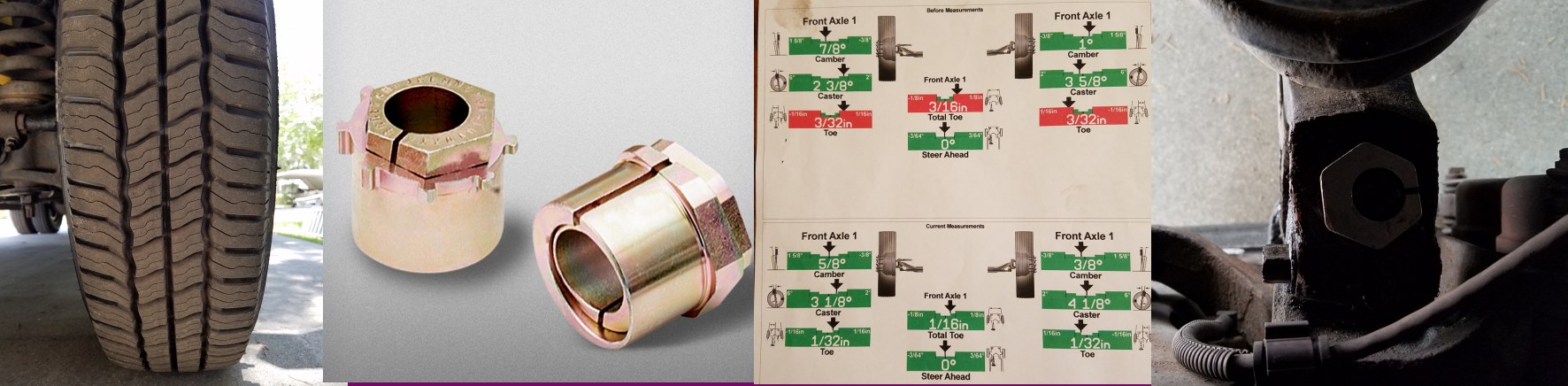

New Front Tires The thread on our 2016 XPS Rib tires was looking scalloped - cupping. We replaced with new Michelins Agilis and had the E-350's Front end checked. They placed Offset Bushings to correct problems with the camber (wheel inward/outward tilt measured in degrees) and caster (front to back with respect to its own straight down, in degrees) as well as the toe - how much the tires point at each other measured in inches. Toe went from 3/32 to 1/32nds of an inch. Hopefully this corrects the problems with the front end. The previous set of tires likewise had cupping issues.

Last of the 2014 Duallys On our way to the Naples service station

we blow the inside sidewall of the passenger side outside tire. Get there OK and have both remaining rear tires from the Mississippi mishap replaced with new rubber.

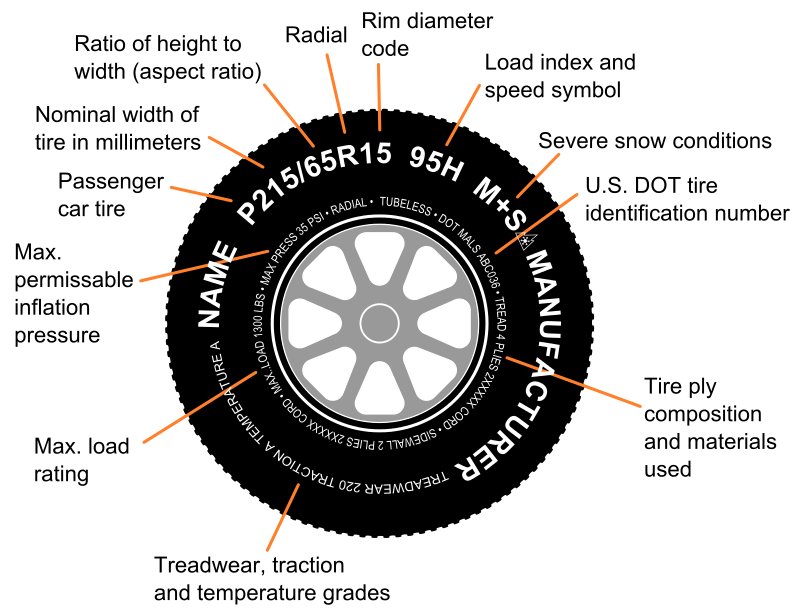

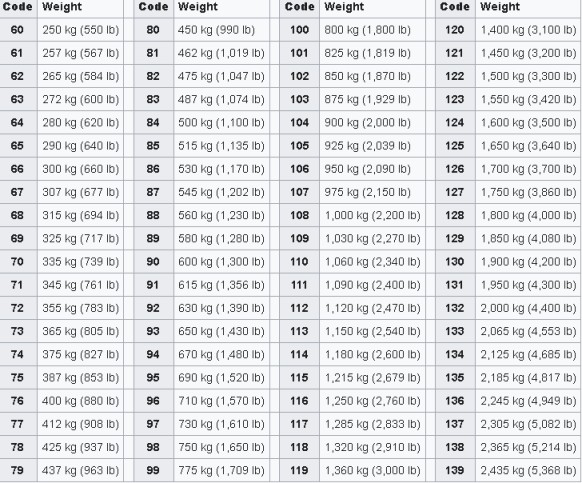

Load Range Understand Tire Service Codes for weight and speed.

Load Range C 101/97[speed rating letter] - Single 1819 lbs/Dually 1610 lbs, 6 ply, 50 psi max.

Load Range D 107/102[speed rating letter] - Single 2160lbs/Dually 1870 lbs, 8 ply, 65 psi max.

Load Range E 115/112[speed rating letter] - Single 2679 lbs/Dually 2470 lbs, 10 ply, 80 psi max.

See chart at bottom of page for additional ranges.

Trailer Rim/Wheel Specification

Rim Size: 15" X 5" (The Rim of the tire by the Tires Measured Width or acceptable range)

Bolt Configuration: 5 Lug 4.5" Center (Measure it - see below)

Offset: 0" (the mounting panel the bolts attach to can be set in or out)

Center Bore: 3.19" (the hole in the center of the rim accommodates the hub.

Rim Construction: Steel (vs aluminum rims that can be weak or need re-torquing)

Rim Style: Modular

Rim Color: Silver

Wheel Hub Diameter: 6.50" (referencing the hub plate the rim attaches to)

Lug Value Hole: 0.45"

Hub Stud Size/Nut Requirement: 1/2"-20 60 Degree Cone Nut

Torque Specifications: 90-120 Ft/Lbs.

Wheel Maximum Load: 2150 Lbs. (Tire cannot be rated for more than the rim)

Trailer Towmax Wear Our passenger side trailer tire (Towmax 205 75/R15) starts to show wires from it's steel belt. 1/2 hour later the problem is worse. We change tire out for spare and find opposite the exposed wires the inside tread is worn down to nothing suggesting out of balance issue.

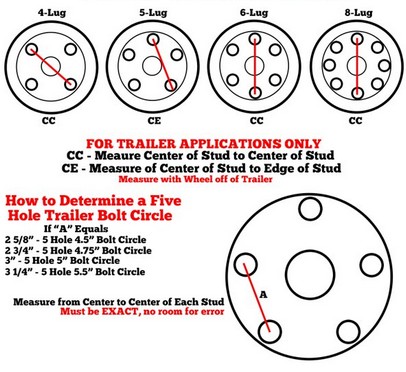

Bolt Pattern Accurate measurements of bolt spacing to ascertain your wheel's bolt pattern.

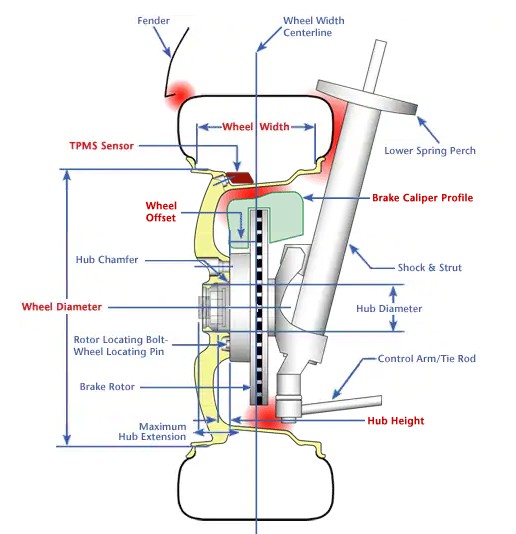

Wheel Rim Width Effects on Tire Width Tires typically specify a Measuring Rim and an acceptable Rim Range. This is with respect to the rim of the wheel; ex 15/5. Differences in the rim width play fractional inch differences in the tires overall mounted width. For example: On a particular tire if the measuring rim is 6 inches and the rim range is 5.5 to 7.5 inches, the tire width varies from 8 to 8.8 inches (0.2 inches for every 1/2 inch rim difference from measured rim)

Wheel Terminology

Bolt Pattern 4 lug vs. 5 lug. There are various versions of 4, 5, 6 and 8 bolt pattern tire to wheel mounting.

Centerbore - The wheel must fit the hub precisely, either as a direct fit or with the use of a centering ring to turn true.

Hub Interference - Many vehicles have additional items on the mounting surface area such as locating pins and rotor mounting hardware that must be considered.

Load Capacity - The wheel must have enough load capacity compared to the vehicles gross axle weight rating.

Suspension Components - The wheel must clear / not interfere with any of the suspension components and their movement range on the vehicle.

5 on 4-1/2 Inch diameter is the "standard" 5 hole lug pattern.

2nd XPS Rib Blows June 2020, on I-95 road northbound on a hot bumpy trip toward the North Carolina boarder, the last stretch before Florence we seeing other downed rigs then ours blew.

Caliper Rebuild Replacing rear rotors required caliper removal. So much easier to rebuild with it out. Removing the caliper required a breaker bar extension. The battery impact wrench would not budge them, though later proved sufficient to later snap one of the mounting studs.

Rotor Replacement After 18 years we finally replace rear Sequoia rotors. About half the rotor surface was completely removed looking like rust underneath. After the rebuild both sides were getting uniformly hot. Stuck pins? Both sides? Mechanical issue seemed unlikely and I am meticulous about detailing bolts. Check master fluid cylinder. (At some point I re-leveled the brake fluid to max) It can not be overfull.

Shredded XPS Rib

I blew one of the XPS Rib tires, drivers side rear, inside tire, inside face. Thread otherwise in great shape. Perhaps I was letting cruise control decide when and where to downshift. The amount of power my Triton V10 can deliver when dropping gears against the inertia generated going up a hill may have presented more torque than the tire could bear. Tires can also slip on the rim. Jeff says that happens in dirtbiking. Perhaps that happened to big Rich's driver front 36ft motorcoach when he got back to Georgia and found it at 30 psi. Here the force might have been braking.

Caliper Drag

Over time the brake calipers may cease to retract sufficiently causing wheel rotation to drag. This can cause a squeaking sound while driving, in our case between 25 - 35 mph that ceases when you apply brake. The mechanics a Defuniak Springs (Google sent us in the wrong direction for 10 miles), thought that brake dust combined with the exceedingly dry weather might exacerbate this issue. One approach is to take the brake mechanism apart and clean it. Another, replacing the whole thing. Remove, inspect and lube the caliper glide pins is also suggested and we took it one step further to spray a small amount of penetrating oil onto the bottom and top slide rails that we suspect might be the source of the dragging. Other information we know from the day is that the brake caliber piston, as it extends further due to the pads becoming less thick may increasingly be less prone to retract. Though the pads are still good, the over extension of the piston might be causing alignment issues that prevent retraction. Another typical symptom of caliper drag is a pull to the left or right, especially off of a start. Ours is still tracking well though they noted drag on both wheels. Our caliper glide pins were in really good shape, the lower right one had some de-lamination of the polished finish. We wiped them clean, greased and re-installed.

New Front Tires

J&J Installed New front tires Michelin XPS Rib, Big Truck service tires on all 6. Quieter than combination tires. We mark and take note of where the balancing weights are. Having lost one it would be good to know their values and locations.

Ball Joints

All 4 ball joints on the Ford E-350 front end had wear. These are the major structural connector of the rotor/wheel assembly to the rest of the suspension. With the front end propped up, using a big bar under the tire, the mechanic was able to demonstrate the up and down play going into the ball joints, there should be little or no play. This type of wear is common to the vehicle. Did the once bad shocks transfer vibration into the ball joints causing them to wear?

Worn Front Tires

The Utah replaced front tires are now showing signs of uneven wear. The right front outside edge is wearing out faster then the inside edge and the other tire and approaching the warning track. Pattern wear on this tire is not normal especially in comparison to the other. Alignment? The vehicle travels straight on a flat road with hands off steering wheel. The original tires wore out prematurely having become "cupped", causing bad vibration. We replaced these while on the road. The mechanics said bad shocks caused stress on the vehicle's suspension and would cause problems. We had the shocks replaced. Now way before even the nominal 20 K miles one can expect from combination tires these are done.

The outside edge of the tire at left is worn out

Front end alignment terminology. With properly aligned wheels tires last longer, easier steering, better gas mileage, smoother ride and less influence from passing trucks.

Caster:

A faulty caster angle causes loose or difficult steering.

Caster describes the steering pivot angle, as seen from the vehicle's side and measured in degrees. Caster alignment plays a large role in evaluating the "feel" of steering and the stability. Three to five degrees of positive caster is typical for most vehicles and lower angles for heavier vehicles.

Camber:

A faulty camber angle will create pulling and tire wear.

Camber is the angle of the wheel in relation to a vertical direction (seen from the front or rear of the car). A negative camber measurement occurs when a wheel leans toward the vehicle's framework; a positive measurement points the wheel away from the car. An ideal camber angle assures optimal tire efficiency, proper steering control, and helps prevent rolling.

Toe:

A faulty toe angle will wear down your tires.

Like camber and caster, toe is measured by degrees. When your front or rear wheels have front edges pointed toward each other, the pair is called "toe-ins." If the front edges point away from each other, the pair is called "toe-outs."

The New Look

Gone the bright shiny hubcaps in favor of being able to easily inspect the hubs, nuts and do quick air pressure checks.(click to enlarge image)

Hole Crud

The below trailer wheel hole at left has crud, Quickly cleaned out with a knife at right.(click to enlarge image)

Hub Crud

The crud on this otherwise fairly new trailer hub is worthy of note. The one on the left has been scraped clean with a knife of paint, accumulated grime and rust.(click to enlarge image)

Nut Inspection

The nuts depicted below - the one to the left is slightly backed off. Can you see the difference? (click to enlarge image)

End Play and Tire wear

My trailer tires had worn laterally on the inside tracks. Although there was remaining good rubber, they otherwise were ruined. We discovered end-play in our trailer hubs, one side worse than the other. With a little propane torch heat and a channel lock pliers removed the axle caps and tightened the castle nut on each side zeroing out the end play while observing the tires to spin freely, re-packed with grease and while exposed oiled the leaf springs. (click to enlarge image)

Trailer Service Tires

Trailer tires and wheels are not built to the same specifications as automobile tires. "For trailer service only" is what you might see on one and means they are built to lesser standards. We always opt to use automotive tires when possible. Some trailer sizes are hard to find. The service industry does not believe in balancing trailer tires. I had to insist to have mine balanced. As RVers we find it beyond belief that there exists separate, lesser standards for trailer tires as there are for Automobile tires.

Wheel Separation

We know that wheel separation usually occurs within 300 miles of the tire being remounted. Without having a complex array of sensors on every truck it is impossible to know what causes this to happen. Usually a tire shreds before metal bolted to metal separates. Upon re-mount, radial forces going into oblongment of the tire (cupping) create greater forces on the wheel to hub connection, usually held in place by the clamping force. The tire might shred. However addition of lateral forces (from end play) reduces the clamping effect momentarily per each rotation of the wheel. The post-remount increased radial force briefly overcomes the clamping force and works directly on the studs causing them to shear or the connectors come off.

Visual Inspection and The Hand Test

Commercial truckers after the spate of incidents in 1991 and new industry guide lines for increased diligence speak of looking at wheels and studs for cracks, wear, rust or separation. The hand test is to simply put your hand on the tire, it should be warm. Hot would indicate loss of bearings or axle oil. Look at where the nut goes into the wheel. It is possible to see when a nut is not deeply seated enough.

End Play

Refers to the amount of play in the tire given the shake test. Usually between 1 and 5 thousand's of an inch. Methods of bearing installation going into pre-load such that the tire is tight on the hub and unable to wobble which speaks primarily to uneven tread wear.

Re-Torque

After removing wheel, the surfaces should be cleaned with a wire brush for good re-contact. Aluminum wheels are especially prone to coming loose. Good shops recommend returning for a re-torque after 15-500 miles some require initialing. Wheel separations can occur from axle failures, hub failures, or fastening failures: most common - when the nuts on the ends of the studs un-thread and fall off [typically on left-side wheels], or when the metal wheel studs break off [typically on right-side wheels]. For both a loss of clamping force is the culprit (corrosion, wear, aluminum).

Stud or Nut failure (Wheel Separation)

Some of the above comes from MEA Forensic where Mark Baily discusses the science. What I don't see addressed is what possible cause could excessive vibration play? Some of us understand that vibration can cause anything to become fatigued or loosen and wonder what part lateral vibration in tire rotation (e.g. Balancing issues) could play.

RV tires For most 5-7 years or 30k miles. Most tires are of blocked pattern, true ribbed equals long milage, low noise highway tires like those on bigger trucks are few in between. Blocked tires typically are good for 25,000 miles max.

ALL tires need to be balanced. (10k intervals)

Did you know that the tire's light spot is identified and marked during manufacture so that the tire shop can install it at the wheel valve assembly (known heavy spot) thereby offsetting or minimizing the unbalance of the assembly.

Dynamic Tire Balancing

A true dynamic balancer will spin the wheel/tire to highway speeds while sensing both the lateral and vertical forces generated allowing for the assembly to be balanced in both planes. Note, that a modest lateral force may never even be noted by the driver but can do great damage (wear) to the suspension components of the RV.

Avoid beads and powders.

Per Goodyear: (When to Balance)

— When new tires are mounted

— When tire and wheel are moved to another wheel position

— When used tires are installed on existing wheels

— After a flat repair or any time a tire is dismounted and mounted

Run-Out (Radial Run-out = oblong rotation)

After mounting the new tire and wheel, check for RUN-OUT. If your installer has a run-out gauge (ex. http://klineind.com/at32000.html) If over .035" run-out correct it by rotating the wheel on the hub. Loosen the lug nuts with the point of most run-out at the top and let the few thousands of an inch play work to your advantage. If that doesn't work have the tires trued. There are still a few shops that do tire truing. A true round tire will last a lot longer. Acceptable measurements range from 0.000 to 0.060 - "I have measured the run-out of hundreds of new Michelin Tires and have never experienced a run out of more than 0.040 in a properly mounted assembly"

Mounted tire balancing If possible spin balance the tire on the vehicle. Balancing all the rotating mass including hub, brake drum or disk is desired. (You don't care where the imbalance is you want it all balanced)

http://www.nexentireusa.com/tires/suv-light-truck/roadian-htx-rh5

NEXEN Roadian LT225/75 R16 115/112Q 10P.R. Load Range E

Hankook DynaPro 115/112Q (Single:2680lbs Dual:2470lbs - Load range E or 10.P.R (listing both radial and sidewall plys) 40 lbs

LT = Light Truck

Load Range E (10 ply) Single 2680 lbs (1215 kg) the 115 rating see: Tire Codes for more info.

Dual 2470 lbs (1120 kg)

Roadian HTX RH5

025092 S2R1 / 0026266

DOT 8EAK BL 1514 (DOT info identifying manufacturer plant and date code 3rd week of April 2014)

Non-LT

Mileage Warranty: 65,000 mi / Road Hazard: 26,000 mi

Road Side Assistance: 36 Months Free Tow & Tire Change

LT

Mileage Warranty: 40,000 mi/ Road Hazard: 16,000 mi

Road Side Assistance: 36 Months Free Tow & Tire Change

L 75 mph 120 km/h Off-Road & Light Truck Tires

M 81 mph 130 km/h Temporary Spare Tires

N 87 mph 140km/h

P 93 mph 150 km/h

Q 99 mph 160 km/h Studless & Studdable Winter Tires

R 106 mph 170 km/h H.D. Light Truck Tires

S 112 mph 180 km/h Family Sedans & Vans

T 118 mph 190 km/h Family Sedans & Vans

U 124 mph 200 km/h

H 130 mph 210 km/h Sport Sedans & Coupes

V 149 mph 240 km/h Sport Sedans, Coupes & Sports Cars

Tire Tread Patterns

Also called tire tread designs, tire tread patterns are the arrangement of continuous ribs, independent tread blocks, circumferential and lateral grooves, as well as the thin sipes molded into the tread to fine-tune noise, handling, traction and wear. Tire treads patterns feature different basic designs to help them meet anticipated driving conditions.

Symmetric Tread Patterns

A symmetric tread pattern is the most common and features continuous ribs or independent tread blocks across the entire tread face where both inboard and outboard halves feature the same pattern. Tires featuring symmetric tread patterns allow using multiple tire rotation patterns.

Asymmetric Tread Patterns

An asymmetric pattern is designed to blend the requirements of dry grip and water dispersal/snow traction where the tread pattern changes across the face of the tire. An asymmetric tread pattern usually incorporates larger tread ribs/blocks on the outboard side to increase cornering stability on dry roads by offering greater contact area. This also helps to reduce tread squirm and heat buildup on the outside shoulder. The inboard side usually features smaller independent tread blocks to aid wet and/or winter traction when driving straight ahead. Tires featuring asymmetric tread patterns allow using multiple tire rotation patterns.

Directional (Unidirectional) Tread Patterns

A directional (also called a unidirectional) tread pattern is designed to roll in only one direction. It incorporates lateral grooves on both sides of the tire’s centerline that point in the same direction and result in v-shaped tread blocks. These grooves enhance hydroplaning resistance at high speeds by pumping water more efficiently through the tread pattern. Unless they are dismounted and remounted on their wheels to accommodate use on the other side of the vehicle, directional tires are to be used on one side of the vehicle and are intended to be rotated from the front axle to the rear axle. If different tire sizes are used on the front vs. rear axle, the tires become location-specific and prohibit tire rotation unless remounted.

Asymmetric and Directional Tread Patterns

Asymmetric and directional tread patterns have v-shaped tread grooves that are offset compared to the centerline of the tire. Tires featuring asymmetric and directional tread patterns must be treated as directional tires for tire rotation. However, if different tire sizes are used on the front vs. rear axle, they become location-specific and prohibit any tire rotation possibilities.

Grand Touring tires and others with asymmetric treads will usually be the quietest, while high-performance directional treads are generally louder.

Tire Noise

The most common noise produced by tires is tire pattern noise. Pattern noise is what people usually are referring to when talking about tire noise; it occurs because air is trapped in the tread pattern and is suddenly released as the tire rolls along the road surface. Tread elements successively hitting the road surface can create what’s known as a rhythmic percussion. Tread designs made up of short, repetitive patterns often generate a whine. Usually, a tire with a rib tread pattern is much quieter than a tire with a lug or block tread pattern.

Tires running higher inflation pressures generate lower noise levels compared to those with lower inflation levels. Radials are much quieter than bias tires, and high speeds result in more noise than lower speeds.

Tires with the same size tread segments all around the circumference of the tire (a single pitch pattern) tend to create significantly higher noise levels than tires with tread blocks of varying sizes and shapes (a multiple pitch pattern). While the multiple pitch patterns each produce different pattern noises, the overall noise level is much lower.

Reducing tire noise by varying the tread pitch pattern is a complicated process. At a minimum, there must be several different pitches placed around the circumference of the tire. But it requires more than simply making several different tread pitches.

Tire Wear and Increased Noise

Tires get noisier as they wear because of their construction, tread design and uneven wear. As a tire wears and the thickness of the tread and its sound insulating properties are reduced, it gets closer to its belts and reinforcements – this can increase tire noise.

Directional tires often get louder as they wear; much more than non-directional tread designs. Tires that are allowed to wear in an uneven manner produce more noise and even steering-wheel vibration. Proper tire rotation and wheel alignment are critical to avoiding such problems, especially with directional tires.

Replacement Tires

Michelins some awesome some not so well receieved, when more than one comment complains about lack of milage. http://www.tirerack.com/tires/tires.jsp?tireMake=Michelin&tireModel=XPS+Rib&partnum=275R6XPSR Michelin Summer Rib $270 long tread life unanimous comment consensus, stable, track, quiet. Cover when parked! A serious looking Truck tire in LT size range. Noe it is 40 lb instead of the usual 32 for tires of this size, another talks of stiff sidewalls.

Bridgestone Duravis M895 also makes a Summer Rib tire but not well reviewed.

Hankook DynaPro effects users fuel milage

"fuel light used to come on around 325-335 miles, now its 290-300. Mileage average was 18.1mpg on old tires hwy/city, now 17.3mpg. Hankook VS previous set" ? Stiff sidewalls, loud?

Summer Rib harder sidewalls, 40 lbs and up, Reported Better Gas milage, lasting high miles, quiet. Start at $174

Snow Tires are for pushing through snow. Some snow tires can't do that.

All Season tend to be warm and rain, snow is a special application requiring two sets of tires.

Goodyear: G949 RSA Amor MAX Over $300 is likewise another ribbed tire contender.

Tire Cupping

"Cupping" or the tire developing flat spots. This is characterized by a shuffing sound most often heard while lowering speed toward a stop. The tire, coming out of round either due to out of balance, under-inflation or general manufacturing processes is generating more noise and evidenced by irregular wear patterns or cracks. Unfortunately even though their appears to be good tread, the tires are increasingly shot and need replacement becoming a blow-out hazard! Below we have a new Michelin Defender and a cupped Bridgestone with crack.

Cupping Talk

Big Rich's rear tires were loud. Later I noticed that some of the blocked tire patterns were black (most were whitish - the back ones were not coming in contact with the road) and was almost impossible to see the cupping. But it made that shuffing noise. Then I noticed the crack. Literally the tire in the process of coming apart. Another incident, we were asked to take the park truck out on the highway and I heard that noise. Though the Truck size USA made Goodyear Wranglers hang tough, after 35 - 40 K miles they start to cup. Upon inspection these had sure visible signs of cupping. We refused the truck.

Another Damaged Tire

This passenger front tire off Lisa's Honda Odyssey. Did the crack (at right) and the hole (at left) have anything to do with each other? (click to enlarge image)

Weight Range Service Codes

|

|

|